|

GEAR2000 -

not only Gears

GEAR2000 is

an application oriented to the analysis and optimization of the gear

pair, connected with working conditions complying with DIN

58400-58405-3960-867, CETEHOR,

ANSI/AGMA 2005-D03.

- Cylindrical gears, parallel axes,

external/internal, straight and helical toothing.

- Cylindrical gears Cetheor specification.

- Bevel gears pair, external straight toothing,

concurrent axes

- Bevel

gears ANSI/AGMA 2005-D03

specification.

- Mathematical dynamical check of steel

worm screw / hostaform gear wheel coupling.

- Lobe Rotors Pump.

- Root Compressor.

- Lubrificating Gerotor Pumps.

- Wankel engine.

- RPS Racks and RPG gears.

- Cylindrical spline mating DIN 5480, DIN 5482, UNI ISO

4156, NF E 22-141, ANSI B92 1-1996, CUNA NC 008-01, DIN 5481, SAE J500, TC-881, UNI 8953 (ISO 14, DIN 14, DIN 5461, UNI 221, UNI 222), SAE type A-B-C, DIN 5471/DIN 5472 and DIN 5462/DIN 5463 (TS 147/15, TS 147/16).

- Synchronous Pulley : UNI 8103 - DIN 7721-2 - AT - HTD.

- Chain wheel ISO 606.

- Non circular gear (Elliptical and Multispeed).

- Single Screw - Co-Rotating / Counter-Rotating Twin-Screw Extruders.

CS

GEAR2000 is interfaced with

other CAM SOFT applications oriented

to the working on CN machine like:

- CS EDM2000

EDM wire profile cutting for dies.

- CS PGL2000

2.5 axes milling and turning.

CS

GEAR2000 evolving every day, in the

last upgrade there are 8 new special profile.

Main functionality :

|

|

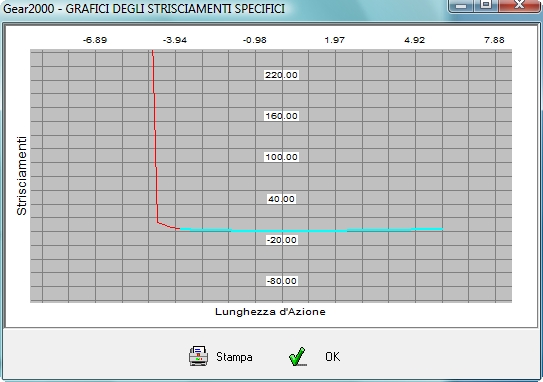

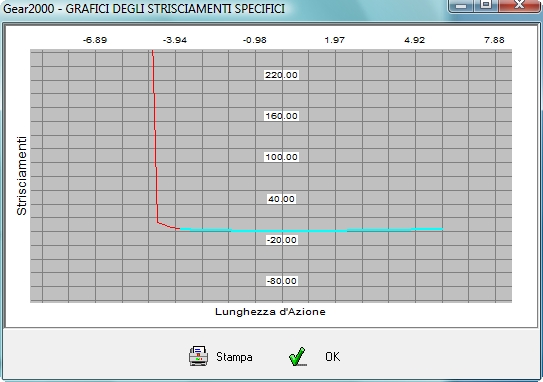

- Negative allowance check, sliding analysis and

balancing with/without

change in distance between centers; advise for the optimized solution.

|

|

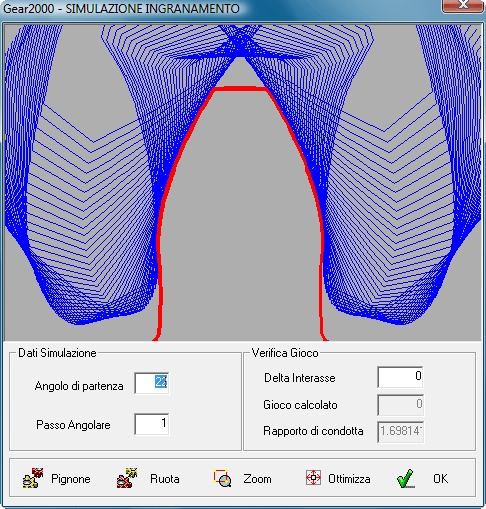

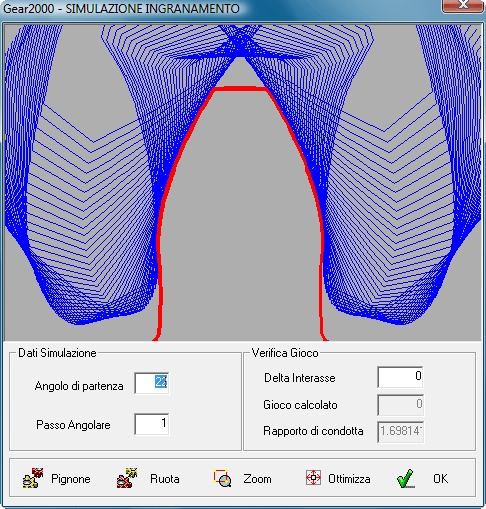

- Mesh graphic simulation and clearance check.

|

|

- Plotting and printing of complete gear data,

complying DIN standard.

|

- Recalculation and check of all

input-parameters, looking for DIN specification; every inconsistency is

displyed, sanction is required to standard dispensation.

- Tooth profile and whole gear generation, output

of CAD file in DXF and MI format.

- Whole gear profile generation, ready to use

on CN Machine (EDM Wire).

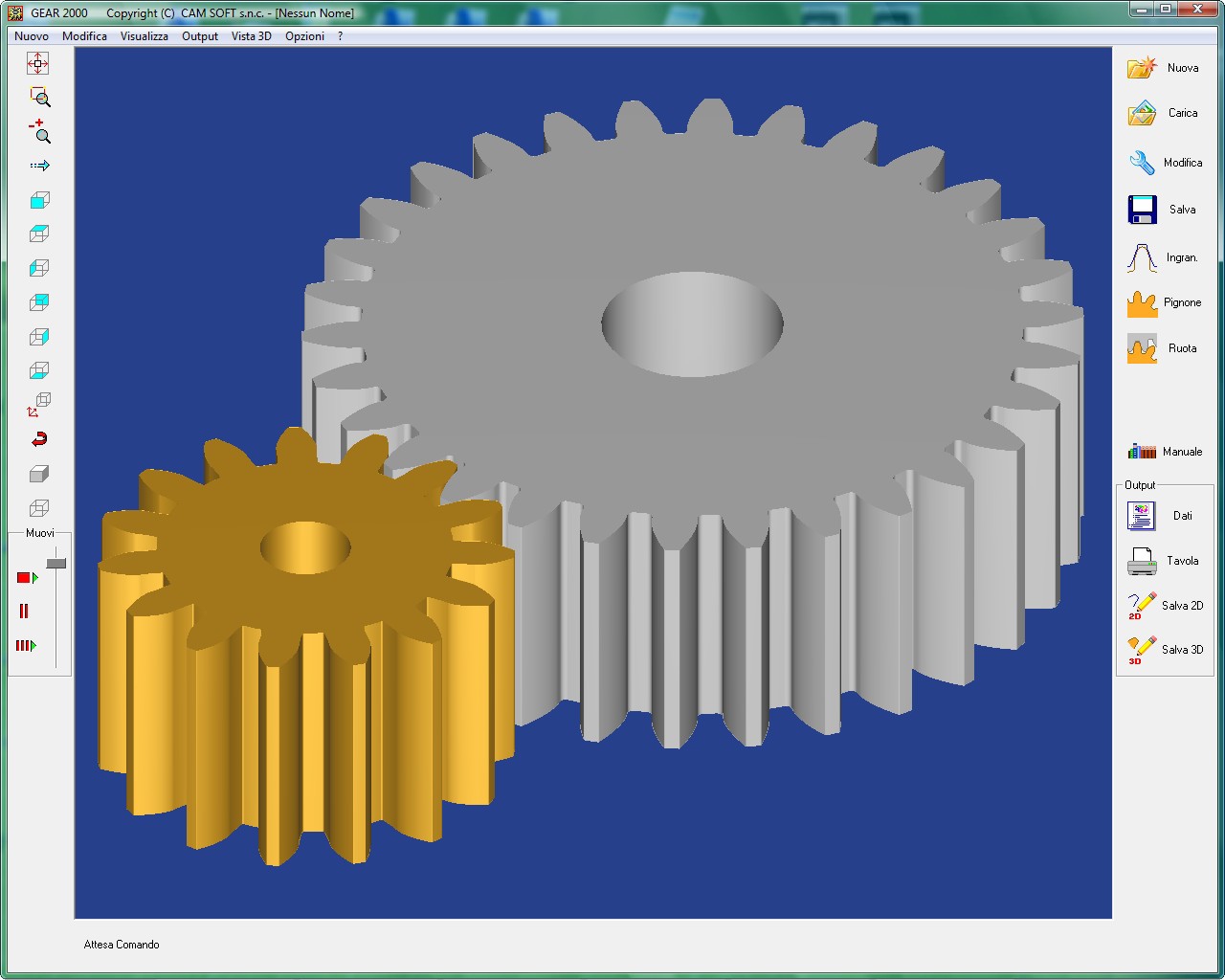

- Solid generation for mesh 3D graphic

simulation; 3D output in Iges3D,STEP, STL and

VRML format.

- Storing and loading design data, modify and

redesign capability.

|

|

|